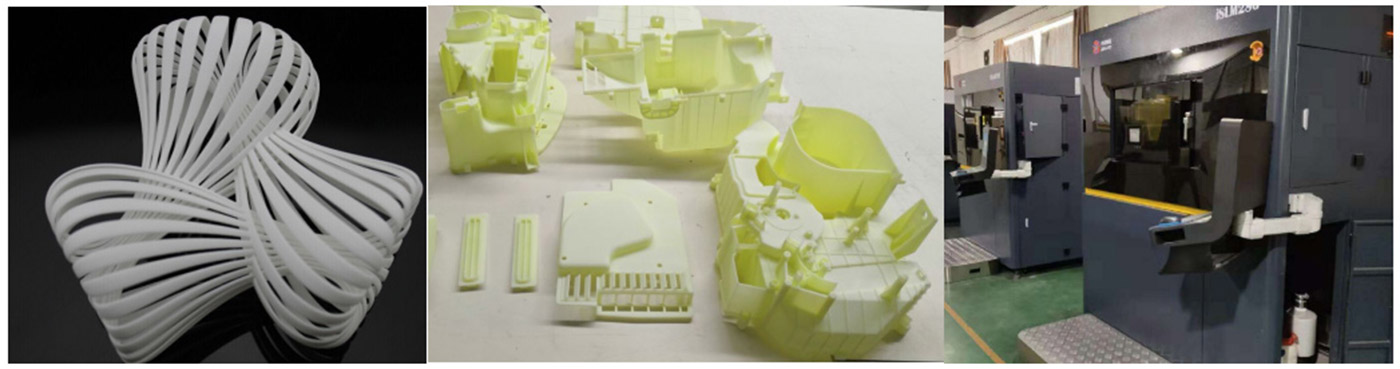

I-SLA (StereoLithography)

• Incazelo: I-SLA ubuchwepheshe bokubumba obulapha isithombe, obubhekisa endleleni yokwakha ungqimba oluqinile olunamacala amathathu ngongqimba ngokuphendula kwe-polymerization kwe-resin photosensitive liquid yi-ultraviolet irradiation. Ucezu lomsebenzi olulungiselelwe yi-SLA lunokunemba okuphezulu futhi ubuchwepheshe bokuqala bokuphrinta be-3D.

• Ukuphrinta Izinto: Resin Photosensitive

• Amandla: i-resin ye-photosensitive ayanele ebukhuni namandla futhi yephuka kalula. Ngasikhathi sinye, ngaphansi kwezimo zokushisa okuphezulu, izingxenye eziphrintiwe zilula ukugoba nokukhubazeka, futhi umthamo wokuthwala awanele.

• Izici zomkhiqizo ophelile: Imisebenzi yokuphrinta ye-SLA inemininingwane emihle nobuso obushelelezi, obungafakwa umbala ngokudweba kwesifutho nezinye izinqubo.

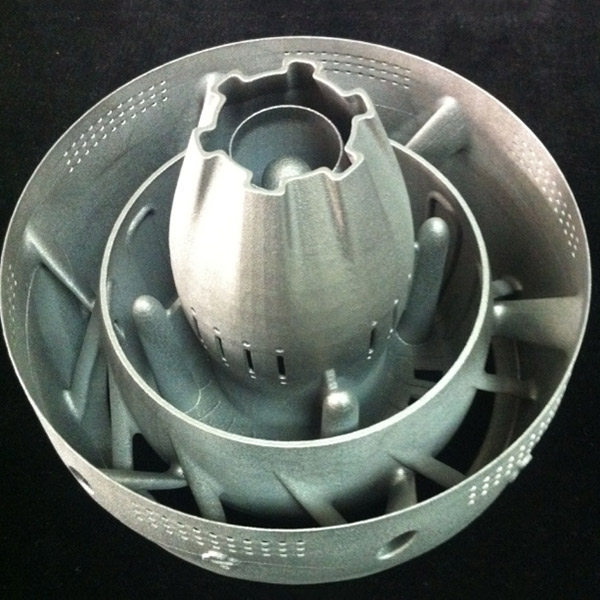

I-Laser Sintering (SLS) ekhethiwe

• Incazelo: I-SLS ubuchwepheshe obukhethayo be-laser sintering, obufana nobuchwepheshe be-SLM. Umehluko ngamandla e-laser. Kuyindlela yokuphrinta esheshayo esebenzisa i-laser ye-infrared njengomthombo wokushisa ukusika izinto ze-powder ze-sinter nokwakha izingxenye ezintathu-ntathu ungqimba ngalunye.

• Izinto Zokuphrinta: Inayiloni powder, i-PS powder, i-PP powder, i-powder yensimbi, i-ceramic powder, isihlabathi se-resin nesihlabathi esigcwele (izinto zokuphrinta ezivamile: inayiloni powder, inayiloni kanye nengilazi fiber)

• Amandla: ukusebenza kwempahla kungcono kunemikhiqizo ye-ABS, futhi amandla nokuqina kuhle kakhulu.

• Izici zomkhiqizo ophelile: umkhiqizo ophelile unezakhiwo eziphakeme zemishini futhi ulungele ukukhiqizwa okuqondile kwamamodeli wokulinganisa, amamodeli asebenzayo kanye neqoqo elincane lezingxenye zepulasitiki. Okubi ukuthi ukucacisa akuphakeme, ubuso besibonelo buqatha, futhi ngokuvamile kuyadingeka ukuthi kupholishwe ngesandla, kufuthwe ngobuhlalu bengilazi, umlotha, uwoyela nokunye okwenziwa ngemuva.

CNC

• Incazelo: Imishini ye-CNC inqubo yokukhiqiza ethabathayo lapho isistimu yokulawula isoftware ikhipha imiyalo yokwenza ithuluzi lenze ukunyakaza okuhlukahlukene okudingekayo. Kule nqubo, kusetshenziswa amathuluzi wokunemba ahlukahlukene ukususa izinto zokusetshenziswa nokwenza izingxenye noma imikhiqizo.

• Izinto zokwakha: Izinto zokucubungula ze-CNC zibanzi impela, kufaka phakathi amapulasitiki nezinsimbi. Izinto ezenziwe ngemodeli yesandla seplastiki yilezi: ABS, acrylic / PMMA, PP, PC, PE, POM, nylon, bakelite, njll .; Izinto eziyimodeli yensimbi yesandla yilezi: i-aluminium, i-aluminium Magnesium alloy, i-aluminium zinc alloy, ithusi, insimbi, insimbi, njll.

• Amandla: izinto ezahlukahlukene zinamandla ahlukene futhi kunzima ukuzibhala

• Izici zomkhiqizo ophelile: Izingxenye zomshini ze-CNC zinobuso obushelelezi, ukunemba okuphezulu, nokuhlangana okuhle kakhulu, futhi kunezinhlobonhlobo zezinketho zangemva kokucubungula.

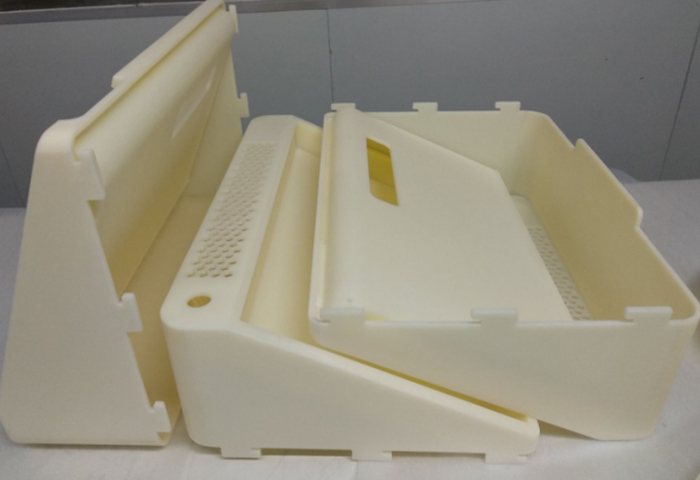

Umshini Ukulingisa

• Incazelo: ubuchwepheshe bokuphonsa umshini ukusebenzisa uhlobo (izingxenye ezisheshayo ze-prototyping, izingxenye zezandla ze-CNC) ukwenza isikhunta se-silicone ngaphansi kwesimo se-vacuum. Ibuye isebenzise i-PU, ABS nezinye izinto ukuzithela, ukuze ikopishe ikhophi efanayo nomkhiqizo womkhiqizo.

• Izinto: ABS, PU, PVC, abicah, ABS esobala

• Amandla: amandla nobulukhuni kungaphansi kwezingxenye zesandla se-CNC. Izinto ezijwayelekile ze-PU ziqhekekile, ukuqina nokumelana nokushisa okuphezulu kubi. I-ABS inamandla aphakeme, i-plasticity engcono, futhi kulula ukucubungula ngemuva.

• Izici zomkhiqizo ophelile: kulula ukuncipha nokukhubazeka; ukunemba ngokuvamile kungu-0.2mm kuphela. Ngaphezu kwalokho, i-vacuum ekubunjweni kwezingxenye zesandla ingamelana nokushisa okuphezulu kwama-degree angama-60, futhi ingaphansi kwezingxenye zesandla se-CNC ngamandla nobulukhuni.

Ubuchwepheshe bokuphonsa umshini busebenzisa uhlobo lomkhiqizo ukwenza abicah abunjwe ngaphansi kwesimo se-vacuum, futhi isebenzisa izinto ezifana ne-PU, ABS njll ukwenza izingxenye ezingaphansi kwesimo se-vacuum esifana ne-prototype yomkhiqizo. Le ndlela ifaneleka ngokukhethekile ekukhiqizeni okuncane kwe-batch.Isixazululo esinezindleko eziphansi ukuxazulula ukukhiqizwa kokuhlola nokukhiqizwa kwe-batch okuncane ngesikhathi esifushane, futhi kungahlangabezana nokuhlolwa kokusebenza kwamasampuli athile wobunjiniyela ngesakhiwo esiyinkimbinkimbi. Sekukonke, ubuchwepheshe bokukhipha i-vacuum busifanele isivivinyo esilula kanye nezidingo zomklamo womqondo.

Izinzuzo ze-Rapid Prototyping

• Izinga eliphakeme lokuzenzakalela ekwakheni inqubo

• Ukuphindaphindeka kwebhizinisi okuqondile

• Ukunemba okuphezulu okuphezulu. Ukunemba ntathu kungaba kuze kube ± 0.1mm

• Ikhwalithi ephezulu kakhulu

• Isikhala sokuklama esingenamkhawulo

• Akukho mhlangano odingekayo

• Isivinini esakha ngokushesha nesikhathi esifushane sokulethwa

• Ukugcina izinto zokusetshenziswa

•Ngithuthukisa ukwakhiwa komkhiqizo